With active parents, it is no wonder that Russell often has many jobs on the go at once. Having recently retired as a metal fabricator and engineer at Pioneer Hi-Bred after 31 ½ years, Russell is certainly not kicking up his heels or resting on the porch. He runs his tree farm, sawmill, custom plants trees, does a little consulting and welding, and is planning on taking more time to go fishing with his wife Chris.

Chris and Russell met over 23 years ago. They married only a few months later, and have never looked back. Between Russell and Chris, they have raised six children and enjoy their grandchildren and great grandchildren.

When Russell was employed with Pioneer Hi-Bred, he was a fabricator and engineering technician designing and testing research equipment.

As a tree farmer who has always had some kind of involvement with the woods, Russell has seen a lot of good timber being burned or buried. Wanting to reclaim some of the wood, he started researching the purchase of a sawmill.

Russell first read about Peterson Portable Sawmills in the widely circulated US magazine, Sawmill and Woodlot. He was impressed with the product’s versatile cutting ability. “I saw I could cut logs 36”+ in diameter, double cut without turning the mill head, and the vertical sizing was at one location which would mean less walking.”

Peterson’s swingblade mill has one circular blade that pivots from the horizontal position to the vertical position cutting one board off a log at a time. This is an efficient way of getting lumber from logs, and without the need for other major equipment such as re-saws many customers agree that the Peterson is an affordable option.

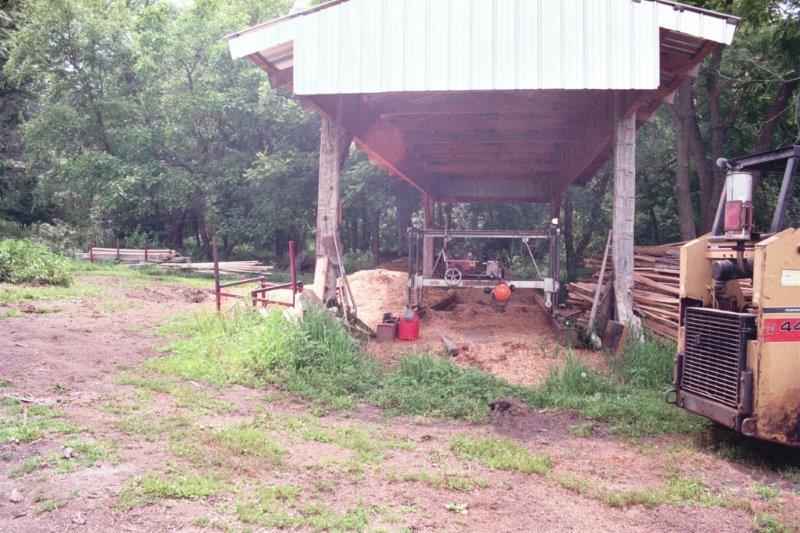

Because of this, in 2002 Russell purchased an 8” 24hp Peterson WPF (Winch Production Frame) and operates it at his 47 acre farm. Russell custom mills oak, walnut and other tree species by request, and also cuts lumber for personal use. He takes the mill to customers if they have more than 15-20 logs over 24” diameter. When he started sawing, 95% of the work was on the road, but now 99% of sawing is done from Wilkins Tree Farm.

To transport his mill, Russell has built a tandem axle 16’ long flat bed trailer, which he tows with a one-ton truck. He also takes along his portable gas engine capstan winch with 7000lb test rope, which Russell said, “comes in very handy”. When milling at home, Russell has all the tools a one-man operation needs – he uses a skid loader with forks and a grapple, a tractor and a homemade log arch to make logs easier to manage.

In the winter of 2007/08, there were several ice storms in Russell’s area that made a layer of ice up to 1” thick on everything, including his mill. It took him over three hours to get the ice off the mill alone! Unfortunately, there was still too much ice to keep working and Russell was shut down for three months and had to postpone some work. Because of this, Russell is currently sawing lumber from trees on his own farm to make a shed for his Peterson sawmill so he can continue working during the winter months.

Peterson Portable Sawmills’ main office and factory are based in New Zealand, and Russell has been very impressed with the company’s service – they can be contacted by phone seven days a week and have representatives serving mill owners in many parts of the world.

When asked if he could suggest any improvements for the company and products, Russell told Petersons to “Keep up the great work!”