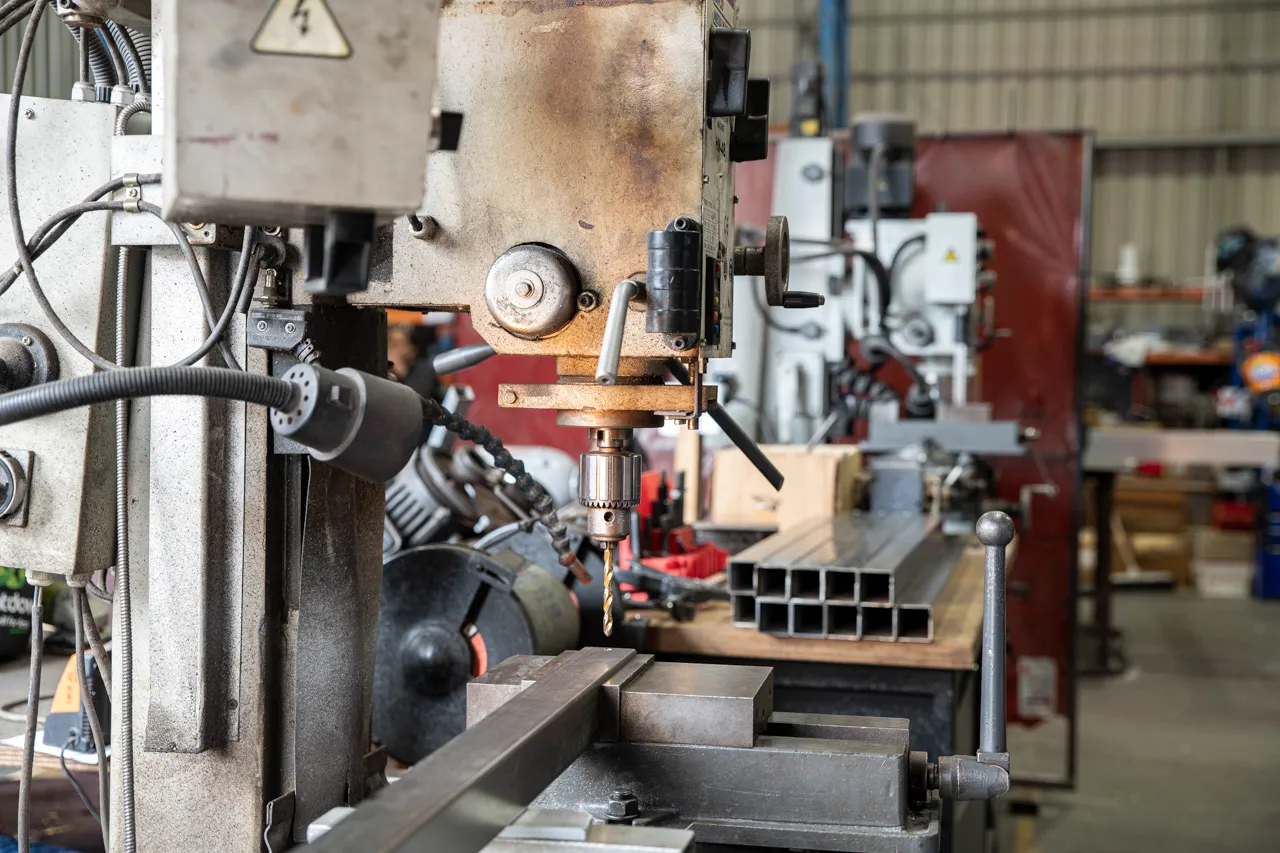

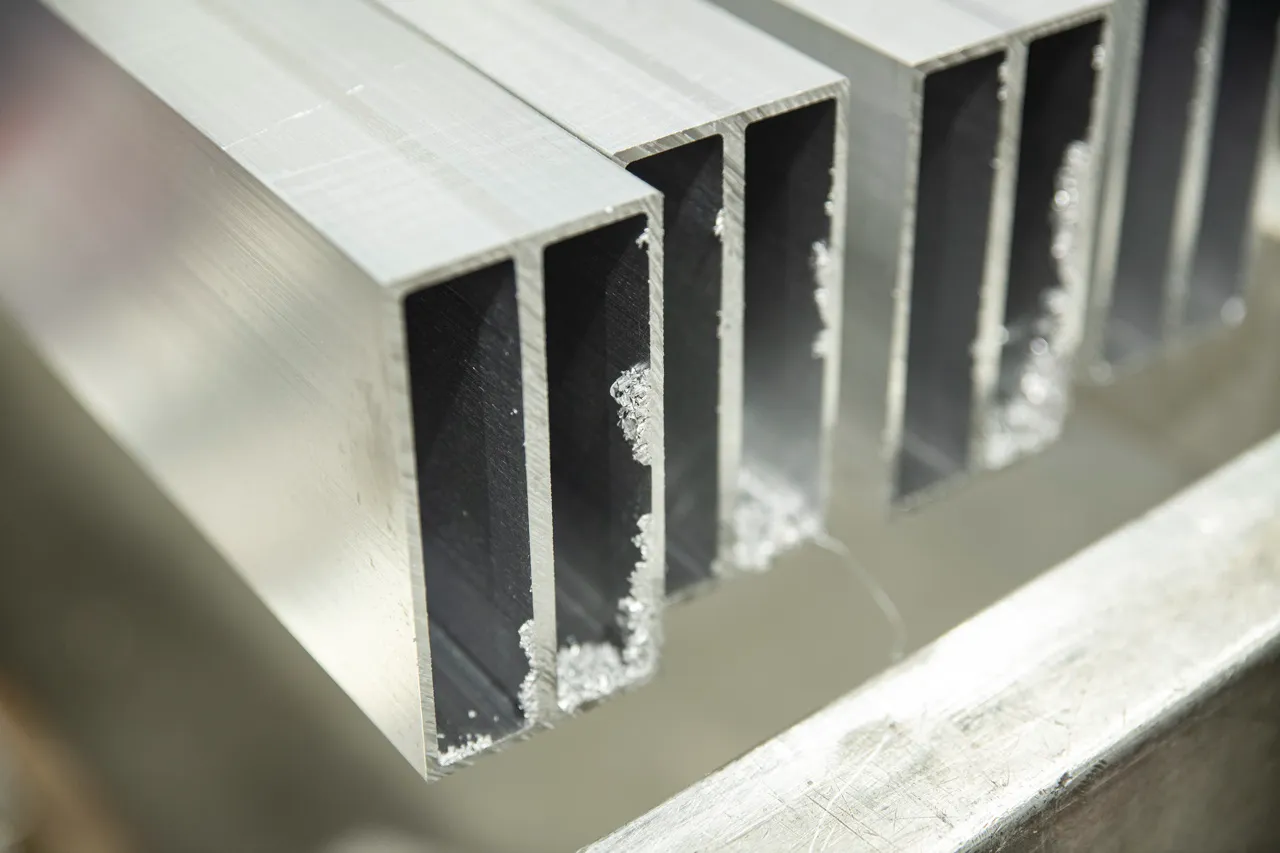

We don’t aim for the budget end of the market with cheap components and “bolt together” kit set sawmills. We don’t use plastic guards and apart from the Junior Peterson, all our sawmill frames are welded stainless steel and aluminum.

These beautiful, high-quality welds are the work of our two full-time welders, Pat Teinaki and Tai Apo. Pat and Tai each bring well over ten years of experience to the welding table. Peterson sees their quality employees as an extension of their brand and keeps the right people long-term. Pat has been with the company for over 20 years, and Tai had a short stint away, but the bond is strong – here’s a newspaper article with her from 2010.

Both of these classy welders were originally interned and trained by our very first aircraft welder, and the skill and presentation live on. Their skills go into creating every sawmill frame, track support, cant hook, and re-tipping jig. If it’s welded, they’ve made it. Building custom-made sawmills is teamwork and, going by the positive feedback, the Peterson team seems to be doing a great job.

It’s not just the welds that are finished to a high standard. All aspects of each finished sawmill are double-checked and have to pass stringent quality checks before leaving the Rotorua factory. No one ever regretted buying quality and perhaps that is one of the reasons we sell so many sawmills. Many “other brand” sawmill owners have swapped their mill for a Peterson. To date, we’re not aware of any Peterson owners selling to buy a Wood-Mizer, Turbosaw, Lucas Mill, D&L, Mahoe or other sawmill.