Peterson Blades

Product Description

One of the best features of Peterson’s range of portable sawmills are their circular blades. When people discover just how low-maintenance they are, they can hardly believe it, especially if they’re used to the maintenance and replacement costs of a band saw blade.

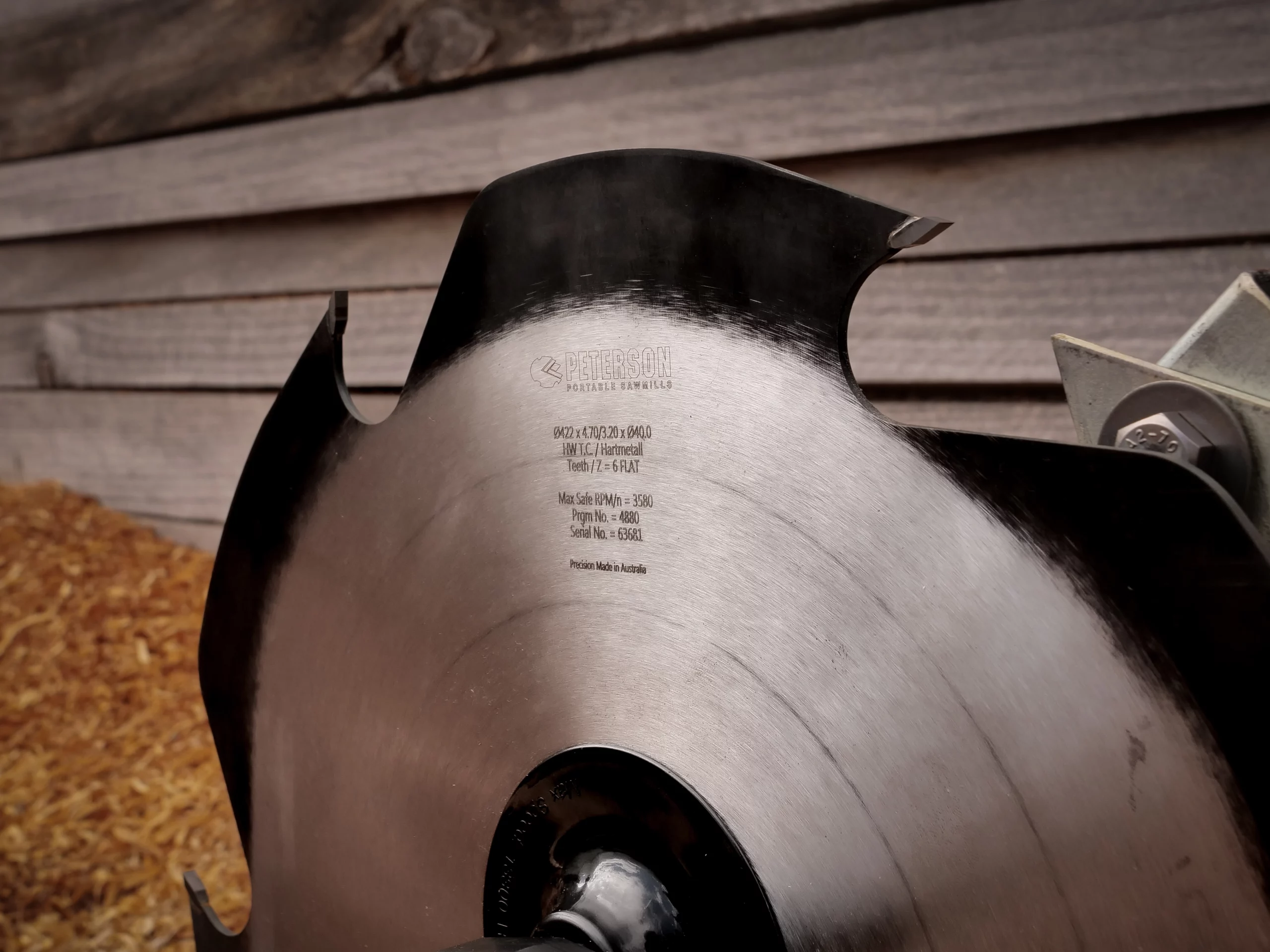

A construction of high-grade steel with solid tungsten carbide tips ensures these blades are built to last. This heightened build quality is a major factor in the increased reliability and decreased maintenance costs of Peterson sawmills.

These blades can also be easily sharpened by the operator in around five minutes. Unlike most competitors, our blade sharpening process takes place without the need to remove the blade from your mill, which is another way that Petersons saves you time and money. The circular blades generally last up to six years with normal use, and reports have even been made of blades lasting over a decade.

Petersons blades are also industry leading for kerf, durability, and precision. The standard Petersons 6” cut blade has up to 32% less Wastage/Kerf then it’s closest swingblade competitors, all while retaining a thicker plate size. What does that mean? It’s simple really – Stronger blades, less repairs, straighter milling, and less wastage. And the 6” Blade is no outlier; The standard 8” cut blade also has up to 21% less wastage/kerf then it’s closest competitors and still retains a thicker plate size.

Features

Built to Last

Peterson Sawmills’ 6″, 8″ and 10″ circular blades are made from high-grade steel, with solid tungsten carbide tips. The tips are easily sharpened by the operator in around five minutes and can be replaced when they’re worn.

Save Time and Money

With the ability to sharpen Peterson’s circular blades in around five minutes without having to remove them from the mill, maintenance costs are minimal.

Low Maintenance

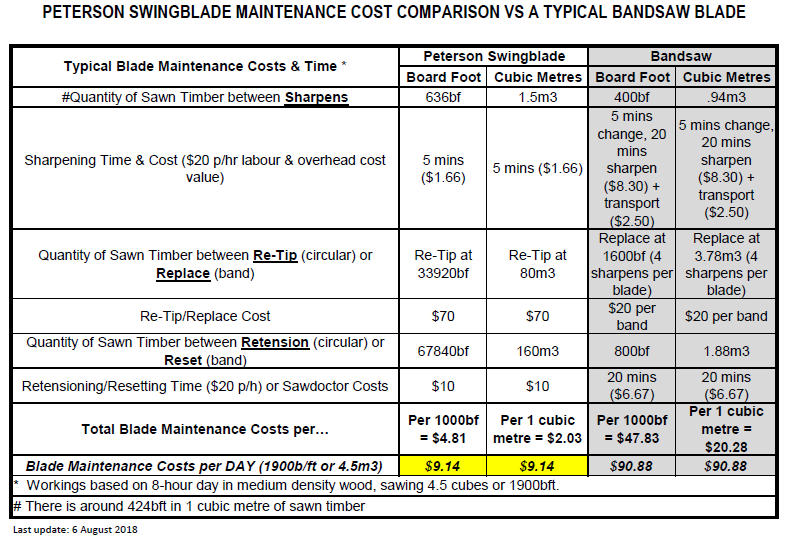

Setting aside for the moment the arguments between bandsaws and swingmills regarding production rates and recovery rates, lets look at typical blade maintenance costs only. This is assuming both mills cut exactly the same amount of timber (1900bft or 4.5cubes) in an 8-hour day, and that neither hit metal. Here is a pretty comprehensive table that has been drawn up from data from two operators using the two different machines in the field. Typical blade maintenance costs and usage periods like these can also be found on the forums mentioned above.

Often purchased with

ASM (Automated Swingblade Mill)

Commercial swing blade – unmatched production at the push of...

WPF (Winch Production Frame)

The contractor’s sawmill – portable or fixed site milling in...

ATS (All Terrain Sawmill)

The best choice for remote locations – Tackle jungles, forests...

WPF + DWS Combination

The ultimate portable sawmill package – offering unbeatable versatility