Many people in the portable sawmill community know Chris Browne or have at least heard of him. Born and bred in Rotorua, New Zealand, Chris is a typical DIY Kiwi bloke who can put his hand to anything. He is also Peterson Portable Sawmills’ Factory Manager and Designer and as such, has played a crucial role in shaping the company over the last 30 years.

With a background in automotive engineering, heavy earth moving equipment, farming and manufacturing, Chris has a great insight to the uses and practicalities of machinery.

Chris’s first working role as a farm hand at age 15 taught him to think outside the box which shaped his ‘number 8 wire’ creative mentality.

Peterson Portable Sawmills’ current CEO Kerris Browne (nee Peterson) ‘discovered’ Chris at the age of 18 and invited him into the Peterson business. He fit in perfectly, and promptly set to work making the machines more user-friendly, stronger, more reliable, and simpler to build.

“When I was still at school,” said Chris, “my teachers told me I had to make a choice between working with wood or metal, now I was working with both!”

In 1989 Kerris’ dad Carl Peterson designed the world’s first commercially-available portable sawmill. Carl initially built the machines in his garage at home, each one different from the last. As each new idea came to him, he would go ahead and add it to the next machine. As the number of orders increased Carl moved the business to a commercial factory site, but the manufacturing process needed refinement.

Chris’s natural ability to design product improvements and implement them efficiently in a production line was just what the company needed. As a result, the various mill models started to look more consistent.

“In the beginning with Carl,” Chris recalled, “every mill looked different. I pointed out how his sawmill designs could be simplified and working together, we made it happen.”

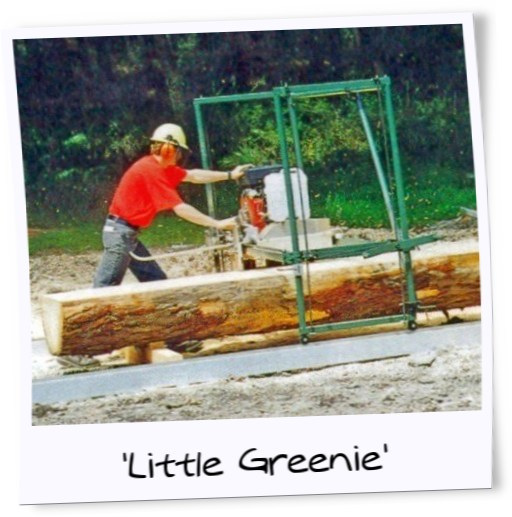

In 1995 Chris started working full time for the company. That’s when he designed the ‘Little Greenie’ model (superseded by the Junior Peterson)

Chris and Kerris have now been married for over 30 years. While Kerris likes paperwork and a busy office environment, her husband Chris prefers to be working outdoors or in the factory. Chris also enjoys attending trade shows with the mills and relates to Peterson owners fabulously well. He can often be found designing some new gizmo that an operator has asked for.

As Peterson’s primary sawmill trainer, Chris has travelled the world to instruct new sawmill owners and to set-up and fine-tune their machines for the local environment. A true globetrotter, he has assisted many millers from his home in New Zealand to Australia, Peru, Chili, Africa, Papua New Guinea, most of the Pacific Islands nations, USA, Canada, UK, Ireland, France and Scotland.

“I enjoy meeting new people from all over the world and find I gel well with most millers, who usually tend to be friendly country-side people.”

When Chris and Kerris took over the company in 2003, one of the first things he set out to do was examine any previous warranty claims. He prioritised all the issues that were being reported and worked on implementing improvements that could be retrospectively added to all the mills that had already been sold.

“Back then we were using small gearboxes that would wreck the bearing within them,” Chris remembers. “The solution we initially came up with was to use a larger gearbox but that would still wreck the higher quality bearing. In the end I engineered an outrigger bearing that goes on the end of the shaft. By adding this second bearing, the gearbox could now handle triple the load. We’re still using this improvement on our mills today.”

In 2019 Chris’s team in the Peterson factory have been working hard to keep up with the increase in orders. With some exciting changes in the works for 2020, this currently limits the time Chris can spend on new product development and field testing.

“Nowadays our sawmills are high-quality, functional machines, but I still like to spend time making further tweaks and small improvements. Right now though, there’s no time to do any of that. Most of my time is spent welding, testing and fine-tuning new mills, packing them and doing a wide variety of other tasks.”

During his thirty year career in the sawmill industry, Chris has plenty of highlights to look back on. He especially wants to acknowledge the positive impact sawmill technology is having on improving the lives of people in third world countries.

“I once trained villagers in Papua New Guinea. When I returned to the village some time later, I was amazed at the changes the mill had brought: where there used to be just fields, there were now houses, a school and a hospital. The villagers made the most of their local resources to improve the livelihood of their people. Several years after my first visit, their sawmill is still running like new.” “The villagers made the most of their local resources to improve the livelihood of their people”

For a man with sawdust running through his veins it’s no surprise that in his ‘spare time’ Chris runs a custom milling business.

“I really enjoy milling and take on small custom sawmilling jobs when I can find the time, mainly in the weekends. I’ve just sourced some gum and macrocarpa that I’m turning into sleepers and special orders.”

His go-to mill is the 10” Winch Production Frame with a powerful 37hp Vanguard motor and electric winch for vertical sizing. “The electric winch makes life so much easier when milling on your own, it’s incredibly accurate.”

When he’s not building or operating sawmills, Chris enjoys running in the forest, cycling, fishing, watching sport and cruising on his Yamaha R6 Supersport motorbike. He officially retired from long-distance running, after completing the Great Wall Marathon in China earlier this year. Chris won’t be retiring from sawmilling anytime soon though, and we’re pretty stoked about that.